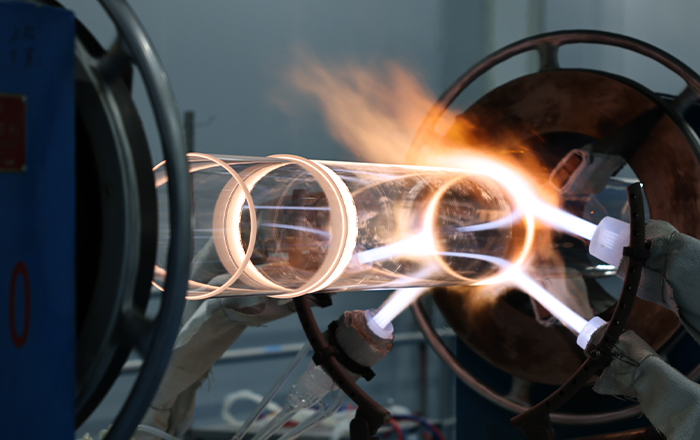

With CNC slotting machine, vertical machining center and all kinds of grinding machines and other production equipment; From the customer drawings and design, with quartz processing cutting, cutting, grinding and other processes, the processing precision excellence.

-

Industry experience:

Industry experience:Futong Quartz has been deeply engaged in the field of photovoltaic and semi-conductor quartz parts manufacturing for 14 years and has accumulated rich industry experience. We have always focused on providing customers with high-quality quartz products, which have won wide recognition in the market.

-

Scale production:

Scale production:The company has 28000m of modern factory workshops, equipped with advanced production equipment and processes. The strong production capacity of the plant enables us to take more orders and meet the large volume needs of our customers.

-

Reliable materials:

Reliable materials:We understand the importance of raw material quality to quartz products. Therefore, the company has established a strict raw material procurement and inspection process to control the purity and quality of quartz raw materials from the source to ensure that each batch of raw materials meet our high standards.

-

Strict quality control:

Strict quality control:The company strictly implements total quality management in accordance with ISO9001-2015 standards, selects and audits raw material suppliers, tests and compares incoming materials, and ensures that each process meets the quality requirements.

中文简体

中文简体  English

English